Q/C Inspect Moulds:

1.Mould Material Q/C

- Mould Steel Checking(Hardness, Crack ,Blow hole material defects )

- Mould Standard Spare Parts Checking(hardness, size, flaw checking)

2. Mould Machining Process Q/C

- Design checking (Part design, mould design,Including 2D drawing and 3D drawing)

- Each part of mould’s size checking after machining according to 2D drawing

- Mold Test (check mould running conditions and T1 samples)

3.Make sure to follow and checking each points of customer’s request before shipment

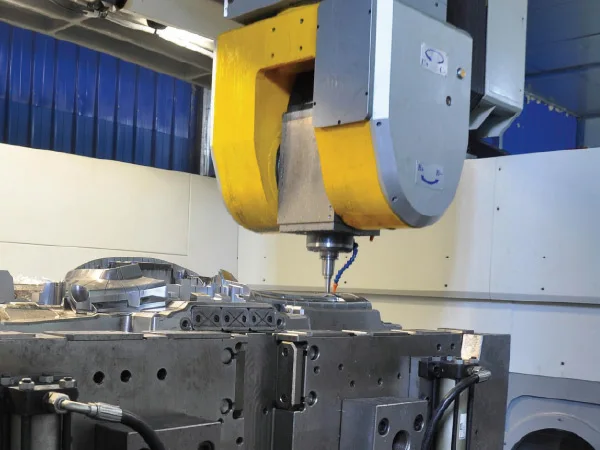

Our Equipment:

|

Machine

|

Working Range

|

Positioning Accurary

|

Work-piece Accurary

|

Max Spindle Speed

|

|

CNC Milling Machine

|

2500mm*1950mm*1100mm

|

0.002mm

|

0.02mm

|

0-4000rpm

|

|

HS Machining Center

|

1200mm * 800mm * 500mm

|

0.001mm

|

0.01mm

|

0-24000rpm

|

|

EDM

|

4000mm * 1700mm * 1000mm

|

0.002mm

|

0.02mm

|

---

|

|

Wire EDM

|

700mm * 450mm * 500mm

|

0.01mm

|

0.02mm

|

---

|

|

Low-speed Wire EDM

|

600mm * 400mm * 350mm

|

0.001mm

|

0.002mm

|

---

|

|

Deep-holedriller

|

2400mm * 1500mm * 1200mm

|

0.001mm

|

0.02mm

|

0-6000rpm

|

|

Item Name

|

Specification

|

Origin

|

Quantity

|

|

EDM

|

DK7740

|

Hangzhou

|

5

|

|

Die-spotting Machine

|

LS-200T

|

Ningbo

|

1

|

|

Drilling Machine

|

|

Hangzhou

|

4

|

|

Precision Horizontal Surface Grinding Machine

|

KGS-250

|

Taiwan

|

2

|

|

Hardness Tester

|

Testing Equipment

|

China

|

2

|

|

Coordinate Measuring Machine

|

KRONOS30-15-13

|

Italy

|

1

|

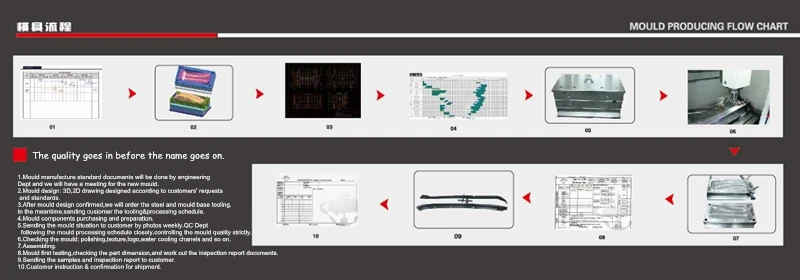

Mould Producing Flow Chart:

Chat Online

Send message to supplier